There are several ways to improve the output and quality of blocks produced by a block making machine.

Some of these include:

1、Using high-quality raw materials, such as concrete and aggregate, that are free from contaminants and properly proportioned to ensure the right mix.

2、Regularly maintaining and cleaning the block making machine to ensure that it is functioning properly and producing consistent, high-quality blocks.

3、Adjusting the settings on the block making machine to ensure that the blocks are being produced at the optimal temperature, pressure, and moisture level.

4、Using a high-quality mold that is well-suited to the type of blocks being produced and is properly maintained to prevent damage or defects.

5、Ensuring that the blocks are properly cured after they are produced, as this can improve their strength and durability.

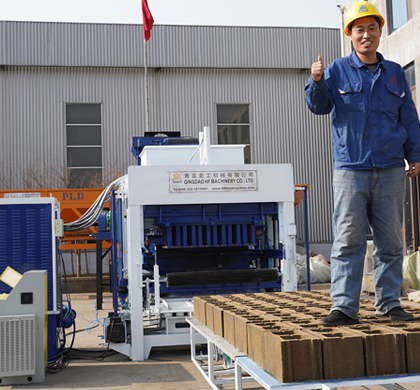

6、Using a block making machine that is designed to produce high-quality blocks and has features that allow for precise control over the production process.

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.